Products

Industries

Aluminum anodizing includes aluminum anodizing and hard anodizing. Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant anodic oxide layer. Aluminum is very suitable for anodizing, although other non-ferrous metals (such as magnesium and titanium) can also be anodized.

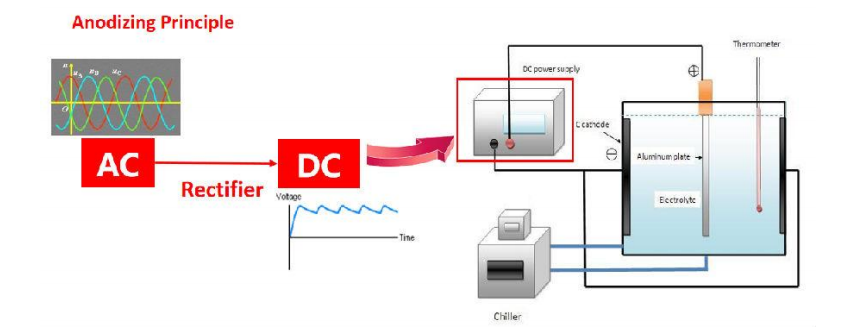

Anodic oxidation, electrochemical oxidation of metals or alloys. Aluminum and its alloys form an oxide film on aluminum products (anodes) under the action of an external current in the corresponding electrolyte and specific process conditions. If anodizing is not specified, it usually refers to sulfuric acid anodizing.

In order to overcome the defects of aluminum alloy surface hardness, wear resistance, etc., expand the scope of application, and extend the service life, surface treatment technology has become an indispensable part of the use of aluminum alloys, and anodizing technology is widely used and successful.

The so-called anodizing of aluminum is an electrolytic oxidation process, in which the surface of aluminum and aluminum alloys is usually converted into an oxide film, which has protective, decorative and some other functional properties.

The metal or alloy workpiece is used as the anode, and an oxide film is formed on its surface by electrolysis. The metal oxide film changes the surface state and properties, such as surface coloring, improving corrosion resistance, enhancing wear resistance and hardness, protecting the metal surface, etc. For example, aluminum anodizing, aluminum and its alloys are placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as the anode, and electrolysis is carried out under specific conditions and external current.

Aluminum anodizing is completed by immersing aluminum in an acidic electrolyte and passing current through the medium. The cathode is installed inside the anodizing tank. Aluminum acts as an anode, so oxygen ions are released from the electrolyte and combined with aluminum atoms on the surface of the anodized parts. Therefore, anodizing is a highly controlled oxidation problem-an enhancement of natural phenomena. Anodizing is generally used to enhance the hardness and corrosion resistance of the product as a surface treatment process. Among them, the materials required to make a set of anodizing equipment include anodes, cathodes, refrigerators, etc., in addition to the anode tank, rectifiers are indispensable.