Products

Industries

Anodizing includes both aluminum anodizing and hard anodizing. It is an electrochemical process that transforms metal surfaces into decorative, durable, corrosion-resistant anodized layers. Aluminum is well suited for anodizing.

The so-called anodizing of aluminum is an electrolytic oxidation process in which the surface of aluminum and aluminum alloys is usually transformed into an oxide film that is protective, decorative and has a number of other functional properties. A metal or alloy part is used as an anode to form an oxide film on its surface by electrolysis.

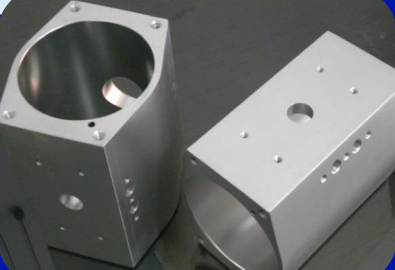

Customer Case 1

TDFB-1000A/40V

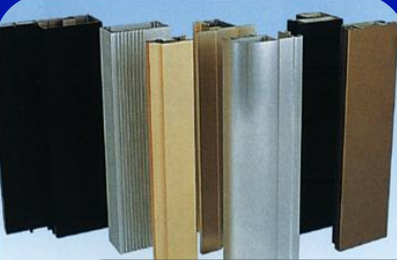

Customer Case 2

TDSB-3000A60V

Ordinary anodizing power supply voltage is generally 18V-24V, current 4000A,6000A,12KA and so on.But hard anodizing (oxide film isthicker), the general voltage ishigher, such as 80v, 100v.At present, the use of high-frequency switching power supplyas an anoxic oxidation rectifier hasbecome a common trend,the advantages of which lie in shorter oxidation time, more energy-saving occupy less space, lighter weight,more convenient maintenance, etc.