Products

Industries

PART 01 Introduction

1.1 Open Cooling Towers

1.1.1 Definition of Open Cooling Towers

The cooling principle of the open cooling tower is that, through the circulating water in the form of spray, sprayed onto the fiberglass filler,

through the contact between water and air, to achieve heat transfer, and then there is a fan to drive the airflow circulation in the tower, will

be with the water after the heat transfer of the hot airflow out, so as to achieve cooling.

1.1.2 Principle of Open Cooling Towers

By spraying the circulating water to the glass fiber packing, through the contact between water and air, to achieve heat exchange, and then there is a fan to drive the airflow circulation in the tower, will be heat exchange with the water after the hot airflow out of the tower, so as to achieve the cooling.

1.2 Closed Cooling Towers

1.2.1 Definition of Closed Cooling Towers

Closed cooling tower (also called evaporative air cooler, closed cooling tower or closed cooling tower) is the tube heat exchanger placed in the

tower, through the circulation of air, outside the tube spray water and the tube of circulating water heat exchange to ensure the cooling effect.

1.2.2 Principle of Closed Cooling Towers

Closed circuit cooling towers operate in a manner similar to open cooling towers, except that the heat load to be rejected is transferred from the

process fluid (the fluid being cooled) to the ambient air through a heat exchange coil. The coil serves to isolate the process fluid from theoutside air, keeping it clean and contaminant-free in a closed loop. This creates two separate fluid circuits: (1) an external circuit, in which spray water circulates over the coil and mixes with the outside air, and (2) an internal circuit, in which the process fluid circulates inside the coil.During operation, heat is transferred from the internal circuit, through the coil to the spray water, and then to the atmosphere as a portion of the water evaporates.

1.3 Comparison of Closed Cooling Towers

All components in an open system must be compatible with the oxygen introduced via the cooling tower. Closed circuit cooling towers completely isolate the process cooling fluid from the atmosphere. This is accomplished by combining the heat rejection equipment with a heat exchanger in a closed circuit tower.

1.3 Chiller

A chiller is a machine that removes heat from a liquid coolant via a vapor-compression, adsorption refrigeration, or absorption refrigeration cycles.

In industrial applications, chilled water or other coolant liquid from the chiller is pumped through process or laboratory equipment. Industrial chillers

are used for controlled cooling of products, mechanisms and factory machinery in a wide range of industries. They are often used in the plastic industries, injection and blow molding, metalworking cutting oils, welding equipment, die-casting and machine tooling, chemical processing, pharmaceutical formulation, food and beverage processing, paper and cement processing, vacuum systems, X-ray diffraction, power supplies and gas turbine power generation stations (see Turbine inlet air cooling#Vapour compression chiller), analytical equipment, semiconductors, compressed air and gas cooling.

PART 02 Solution

2.1 Cooling Tower + Water Cooled Chiller + Rectifier

2.2 Freezer + Circulating Water Tank + Rectifier

2.3 Freezer + Circulating Water Tank + Rectifier

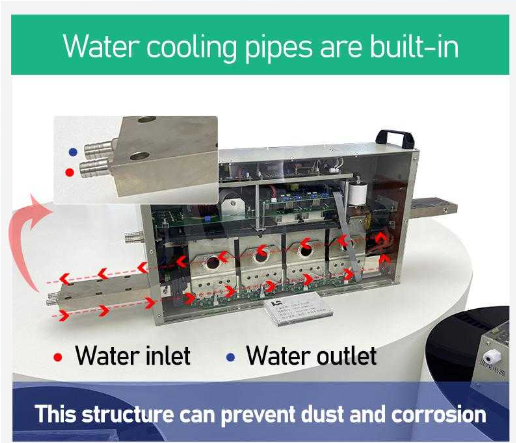

PART 03 Water Cooled Rectifier

Structure and Advantages of Water Cooled Rectifier

Water Cooled Rectifier