Products

Industries

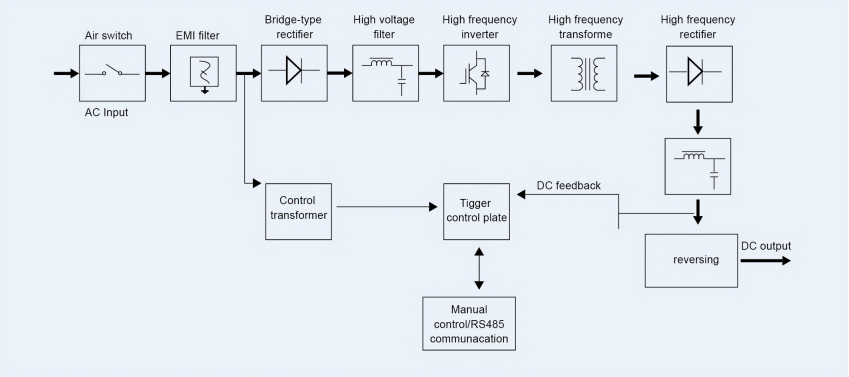

Polarity reversing in electroplating refers to a technique where the electrical current is periodically reversed during the plating process, meaning the anode and cathode are switched back and forth, allowing for a more controlled and even metal deposition on the workpiece, often used to improve surface quality and reduce stress on the plated layer; it's also known as "periodic reverse current plating.

Polarity Reversing Rectifier Advantages

Improved surface finish: By periodically stripping a small amount of metal from the surface during the reverse current cycle, it can help smooth out irregularities and produce a more refined finish.

Reduced internal stress: Reversing the current can help minimize stress within the deposited metal layer, making the plating more durable.

Better adhesion: In some cases, the brief reverse current can enhance the adhesion of the plating to the substrate.

Enhanced throwing power: Can improve the plating quality in recessed areas or complex geometries.

Applications in Electroplating

Decorative plating: Used to achieve high-quality finishes on items like jewelry and automotive parts.

Hard chrome plating: Helps improve the wear resistance of hard chrome coatings.

Plating on complex shapes: Can help ensure even metal deposition on intricate geometries.

Electroetching prior chrome plating: Remove the passive oxide layer that forms immediately on contact with the air.