Products

Industries

Input parameters: Three phase AC380V/440V±10%, 50-60HZ

Output parameters: DC 20-25V 8KA-20KA

Output mode: Common DC output

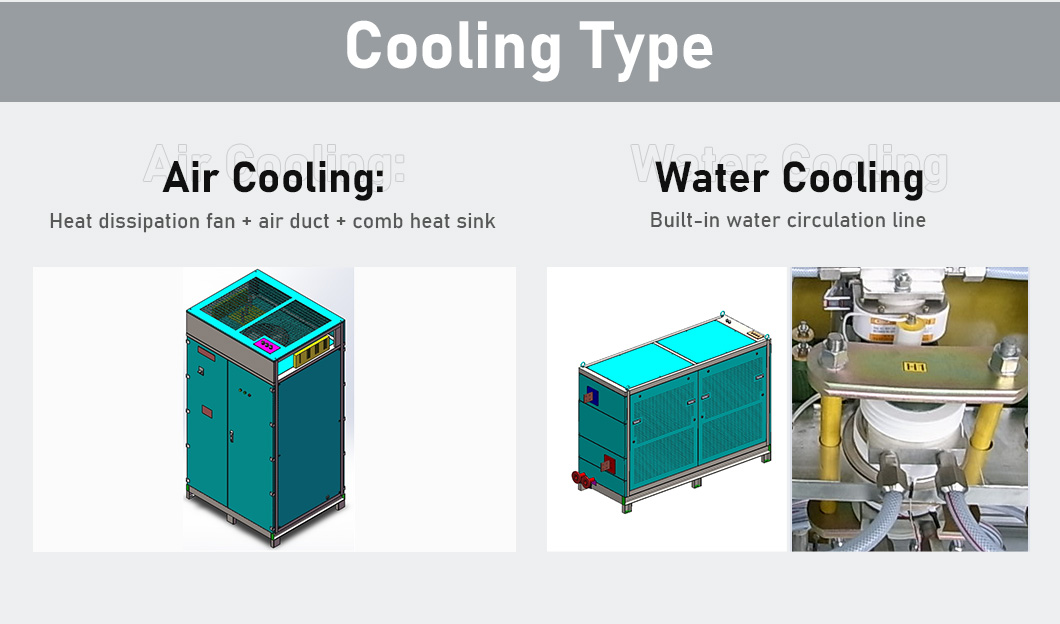

Cooling method: Water cooling

Power supply type: IGBT-based

Application Industry: Plating industry

Anodic oxidation is accomplished by immersing aluminum in an acidic electrolyte and running an electric current through the medium. The cathode is installed inside the anodic oxidation tank. Aluminum acts as an anode, so oxygen ions are released from the electrolyte and combine with the aluminum atoms on the surface of the anodized part. Therefore, anodic oxidation is a highly controlled oxidation problem – an enhancement of natural phenomena. Anodic oxidation is generally used to strengthen the product hardness, corrosion resistance and do surface treatment. One of the materials required to make a set of anodic oxidation equipment in addition to the anode tank, including the anode cathode, refrigerator, etc., rectifier is essential.

General decorative anodic oxidation requires dc power supply voltage is usually 20V-24V, hard anodic oxidation according to the process, the voltage is usually higher, sometimes up to 80V, 100V, 120V, etc., the current depends on the size of the anodized workpiece, from several hundred to tens of thousands of amperes. At present, the use of high-frequency switching power supply as anodic oxidation rectifier has become a general trend, its advantages are shorter oxidation time, more energy saving, less space, lighter weight, more convenient maintenance and so on.

Aluminum oxidation coloring, using artificial methods to make the surface of aluminum and its alloy products to generate a layer of oxide film (Al2O3) and impose different colors, in order to improve the wear resistance of aluminum, prolong the service life and increase the color and luster beautiful. The basic processes of oxidation coloring are surface treatment, oxidation, coloring and subsequent hydration sealing, organic coating and other processing processes.

| Input voltage | Three phase AC380V/440V±10%, 50-60HZ |

| Voltage regulation precision | ≤1% |

| Current regulation precision | ≤1% |

| Rated efficiency | ≥90% |

| Power factor | ≥0.98 |

| Ripple wave coefficient | 1% ~ 3% |

| Operation environment | -10-40℃ |

| Storage temperature | -20-50℃ |

| Inversion frequency | 18KHZ |

| Insulation resistance | Input-output: ≥5MO |

| Input-shell: ≥5MO | |

| Output-shell:≥5MO | |

| Insulation strength | Input-output: AC1500V, 10mA, 1 min |

| Input-shell: AC1000V, 10mA, 1 min | |

| Cooled mode | Water cooling |

| Operation conditions | 24-hour operation under full load |

| Output Voltage | Output Current | Dimensions | ||

| H (mm) | W(mm) | L (mm) | ||

| 20V,22V,25V | 8000A-10000A | 1890 | 680 | 1300 |

| 20V,22V,25V | 12000A | 2242 | 680 | 1300 |

| 20V,22V,25V | 15000A | 2010 | 1540 | 1300 |

| 20V,22V,25V | 20000A | 2280 | 1540 | 1300 |

| *OK to customize as requirements* | ||||

Hot Tags:20~25V 8KA~20KA High Quality Aluminum Anodizing Rectifier,SCR Controlled Rectifier,Anodizing,Coloring,aluminum electrolysis rectifier,Plating industry

If you have more questions, please leave us a message and we will contact you within 24 hours.