Products

Industries

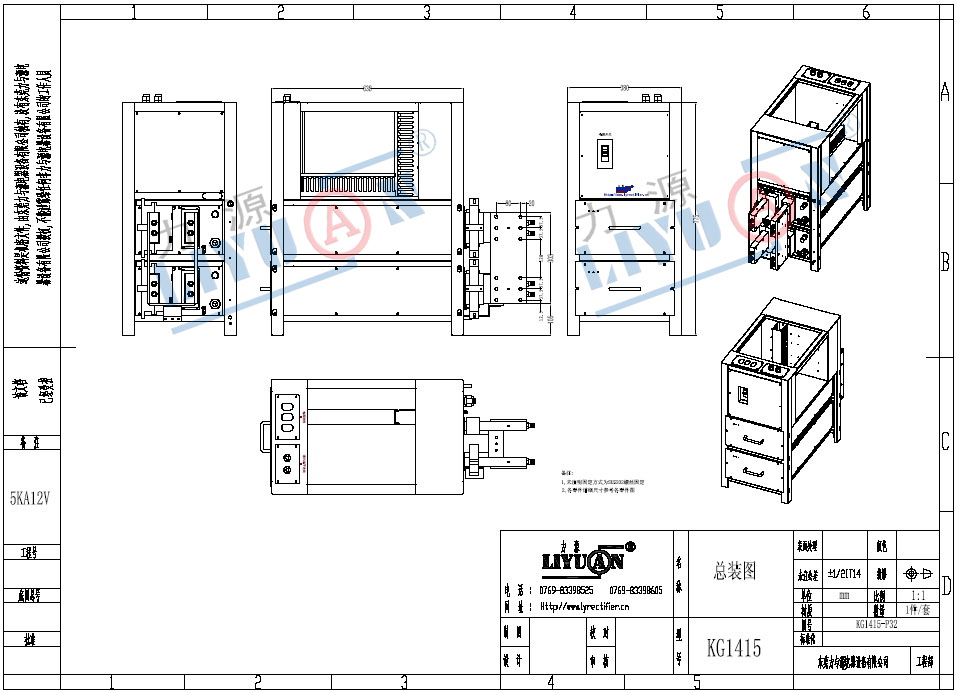

Input parameters: Three phase AC380V±10%, 50~60HZ

Output parameters: DC 0~12V 0~5000A

Output mode: Common DC output

Cooling method: Water cooling

Power supply type: IGBT-based

Application Industry: Surface treatment industry, such as chrome plating

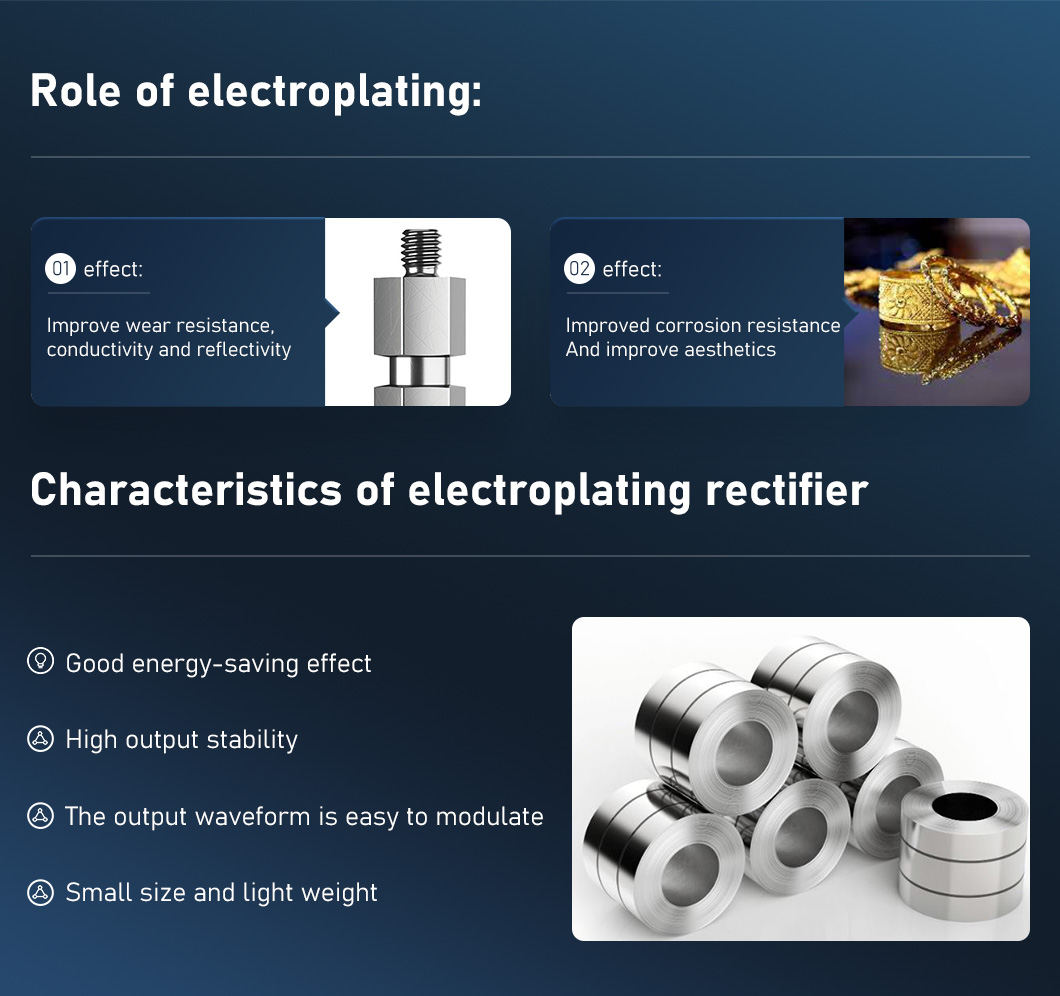

Electroplating is the process of applying a thin layer of other metals or alloys on the surface of certain metals by electrolysis. It is a process of applying a metal film to the surface of metals or other materials to prevent metal oxidation (such as rust), improve wear resistance, electrical conductivity, reflectivity, corrosion resistance (copper sulfate, etc.) and enhance aesthetics.

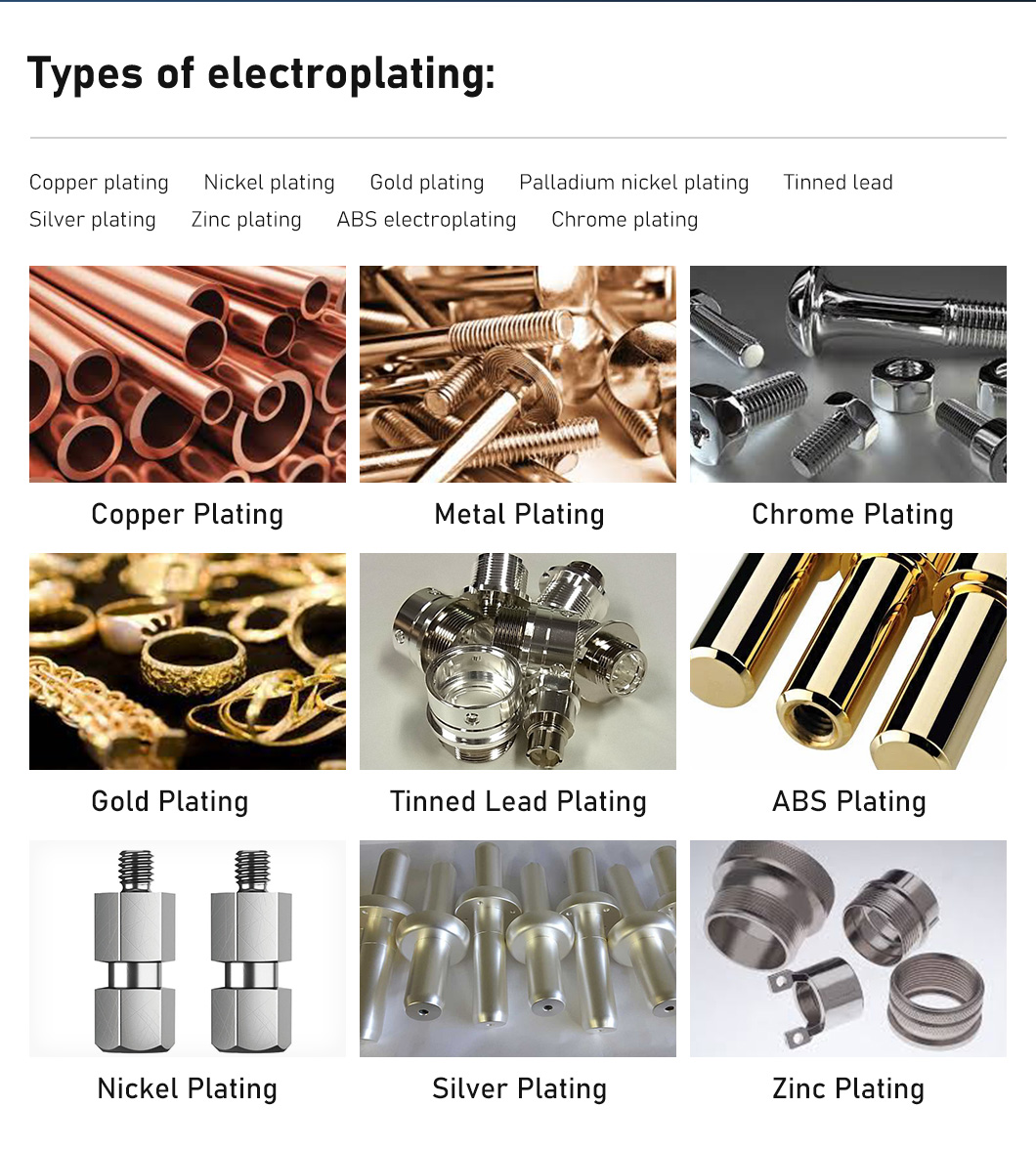

Types of plating:

Copper plating: priming, enhance the ability to adhere to the plating layer, and the ability to resist corrosion. (Copper is easy to oxidation, oxidation, copper green no longer conductive, so copper-plated products must do copper protection)

Nickel plating: priming or appearance, to enhance the corrosion resistance and wear resistance, (where the chemical nickel for the modern process of wear resistance than chrome plating). (Note that many electronic products, such as DIN head, N head, no longer use nickel priming, mainly because nickel is magnetic, will affect the electrical properties inside the passive intermodulation)

Gold plating: improve the conductive contact impedance, enhance signal transmission. (Gold is the most stable, but also the most expensive.)

Palladium-nickel plating: improve the conductive contact impedance, enhance signal transmission, wear resistance than gold.

Tin-lead plating: improve soldering ability, soon to be replaced by other substitutes (because of the lead content is now mostly changed to bright tin and mist tin plating).

Silver plating: improve the conductive contact impedance, improve signal transmission. (Silver performance is the best, easy to oxidation, oxidation also conductive)

Elements of electroplating:

Cathode: the plated object, referring to various connector terminals.

Anode: If it is soluble anode, it is the metal to be plated. If it is insoluble anode, most of them are precious metals (white gold, iridium oxide).

Plating solution: plating solution containing ions of the metal to be plated.

Plating tank: The tank that can bear and store the plating solution, generally considering strength, corrosion resistance, temperature resistance, etc.

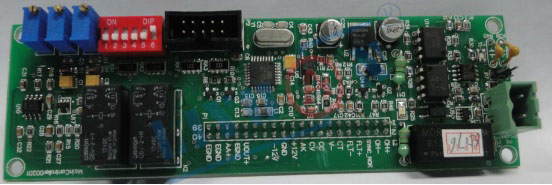

Rectifier: The equipment to provide DC power supply.

Characteristic Types |

Parameter Items |

Technical Requirements |

| Power Types | Power types | High-frequency Power Supply |

| Model and specifications | TBSB-5000A/12V | |

| Cooling mode | Water-cooled | |

| Switch tube type | IGBT | |

| Input Characteristics | Rated Input Voltage | Three-phase, AC380V±10% ,50~60HZ |

| Rated Input Power | 67.2KW | |

| Rated Input Current | AC 102A | |

| Input Power Factor | COSΦ≥0.95 | |

| Output Characteristics | Output Voltage | DC 0~12V |

| Output Current | DC 0~5000A | |

| Stabilized Current Precision | ≤1%(Rated Current) | |

| According to accuracy | 1A,0.01V | |

| Rated Output efficiency | ≥94% | |

| Environmental Conditions | Installation site | Indoor installations |

| Altitude | ≤1500 meters | |

| Ambient temperature | -20℃~40℃ | |

| Relative humidity | ≤90% | |

| Control Mode | Operating mode | PLC, ADDA, Ethernet, RS485 and RS232 |

| Other | Weight | About 30KG |

| External Dimension | Height*Width*Depth | H775mm×W380mm×D638mm |

| Protection Characteristics | With over voltage, over current, overload, short circuit,

overheating and other abnormal self-protection function |

|

| Model | Input | Output | Dimension (mm)/L*W*H |

| TBSB-400A/12V | Three Phase AC380V±10% 50HZ | 12V/400A | 500*343*183 |

| TBSB-500A/12V | Three Phase AC380V±10% 50HZ | 12V/500A | 460*310*185 |

| TBSB-600A/12V | Three Phase AC380V±10% 50HZ | 12V/600A | 500*343*183 |

| TBSB-800A/5V | Three Phase AC380V±10% 50HZ | 5V/800A | 460*310*185 |

| TBSB-800A/6V | Three Phase AC380V±10% 50HZ | 6V/800A | 460*310*185 |

| TBSB-800A/12V | Three Phase AC380V±10% 50HZ | 12V/800A | 780*350*180 |

| TBSB-1000A/12V | Three Phase AC380V±10% 50HZ | 12V/1000A | 644*330*192 |

| TBSB-1000A/16V | Three Phase AC380V±10% 50HZ | 16V/1000A | 620*310*180 |

| TBSB-1000A/25V | Three Phase AC380V±10% 50HZ | 25V/1000A | 700*352*185 |

| TBSB-1000A/36V | Three Phase AC380V±10% 50HZ | 36V/1000A | 700*352*185 |

| TBSB-1000A/38V | Three Phase AC380V±10% 50HZ | 38V/1000A | 780*365*187 |

| TBSB-1200A/5V | Three Phase AC380V±10% 50HZ | 5V/1200A | 580*342*185 |

| TBSB-2000A/5V | Three Phase AC380V±10% 50HZ | 5V/2000A | 780*310*180 |

| TBSB-1800A/12V | Three Phase AC380V±10% 50HZ | 12V/1800A | 780*310*180 |

| TBSB-2500A/12V | Three Phase AC380V±10% 50HZ | 12V/2500A | 1024*340*180 |

| TBSB-3000A/12V | Three Phase AC380V±10% 50HZ | 12V/3000A | 700*352*185 |

| TBSB-3000A/15V | Three Phase AC380V±10% 50HZ | 15V/3000A | 824*340*180 |

| TBSB-4000A/10V | Three Phase AC380V±10% 60HZ | 10V/4000A | 700*362*185 |

| TBSB-4000A/15V | Three Phase AC380V±10% 50HZ | 15V/4000A | 824*340*180 |

| TBSB-5000A/7V | Three Phase AC380V±10% 50HZ | 7V/5000A | 700*362*185 |

| TBSB-5000A/15V | Three Phase AC380V±10% 50HZ | 15V/5000A | 824*340*180 |

| ※Can be customized according to requirements※

|

|||

Hot Tags: 0~12V 0~5000A IGBT-based Rectifier for chrome plating,Hard Chrome Plating Rectifier,Surface treatment industry,rectifier for electroplating,plating rectifier manufacturers

If you have more questions, please leave us a message and we will contact you within 24 hours.