Products

Industries

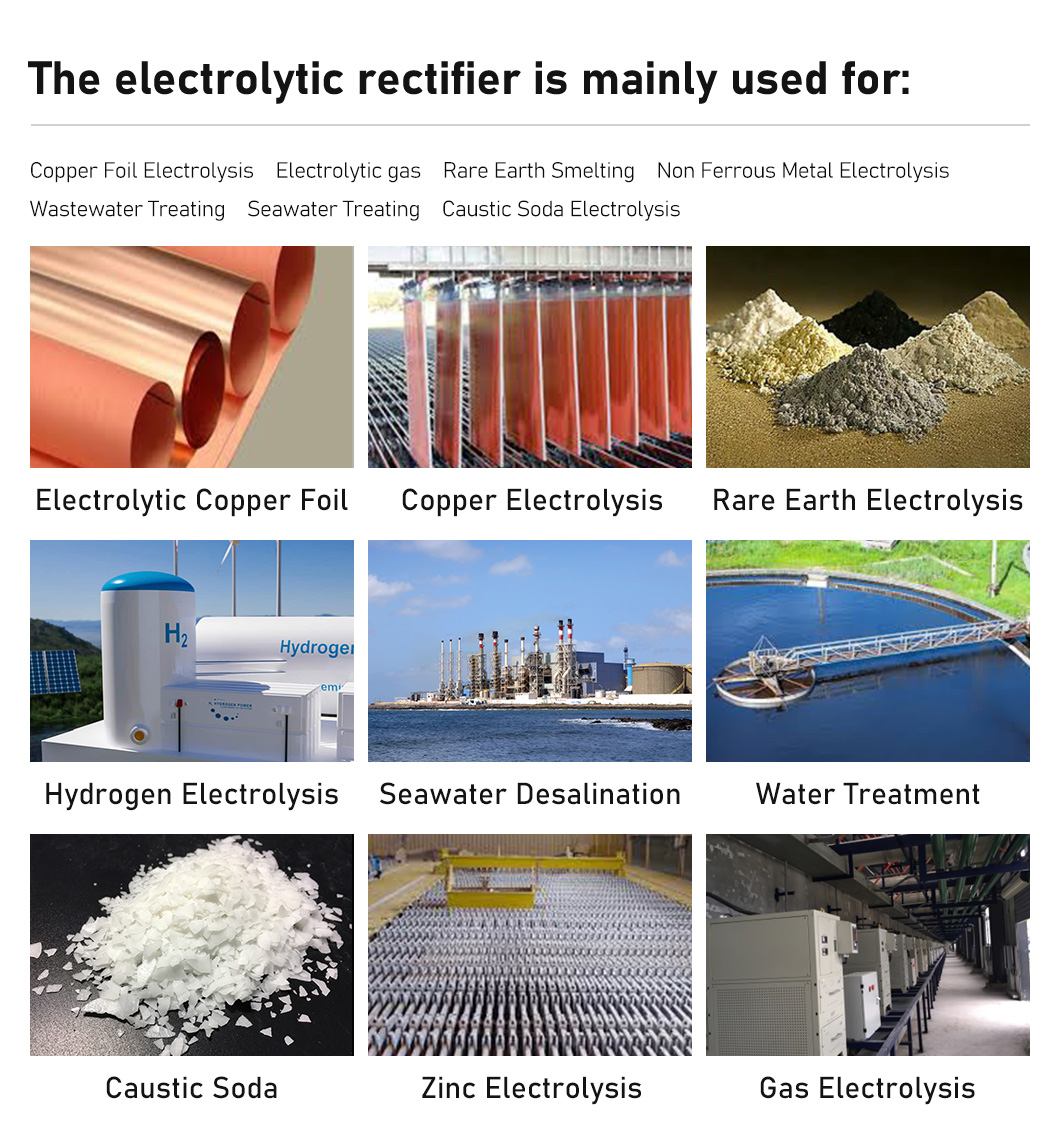

Rare earth smelting rectifier mainly used in heating and electrolytic smelting for rare metal.

There are two methods of rare earth smelting, hydrometallurgy and pyrometallurgy. Pyrometallurgy has simple process and high productivity. Rare earth pyrometallurgy mainly includes silicon thermal reduction method to obtain rare earth alloy, molten salt electrolysis method to obtain rare earth metal or alloy, metal thermal reduction method to obtain rare earth alloy. The common characteristic of pyrometallurgy is production under high temperature. In industrial mass production of mixed rare earth metals, molten salt electrolysis is generally used. The process involves heating and melting rare earth compounds, such as rare earth chlorides, and then electrolysis to precipitate the rare earth metals at the cathode. There are two electrolysis methods: chloride electrolysis and oxide electrolysis. Methods for preparing single rare earth metals vary from element to element.

| Input voltage | Three phase AC380V/440Vac±10%, 50-60HZ Single phase AC220±10% |

| Voltage regulation precision | ≤1% |

| Current regulation precision | ≤1% |

| Rated efficiency | ≥85% |

| Operation environment | -10-40℃ |

| Storage temperature | -20-50℃ |

| Cooled mode | Air cooing, water cooled or oil cooled |

| Operation conditions | 24-hour operation under full load (under 1500m) |

| Output voltage range | 0-100V |

| Output current range | 0-50000A |

| * Ok to customzie as per requirements* | |

Hot Tags:0~100V 0~50KA Industrial Rectifiers For Rare Metal Heating And Electrolysis,Rare Earth Smelting,rare earth smelting rectifier

If you have more questions, please leave us a message and we will contact you within 24 hours.