Products

Industries

Input parameters: Three phase AC380V±10%, 50HZ

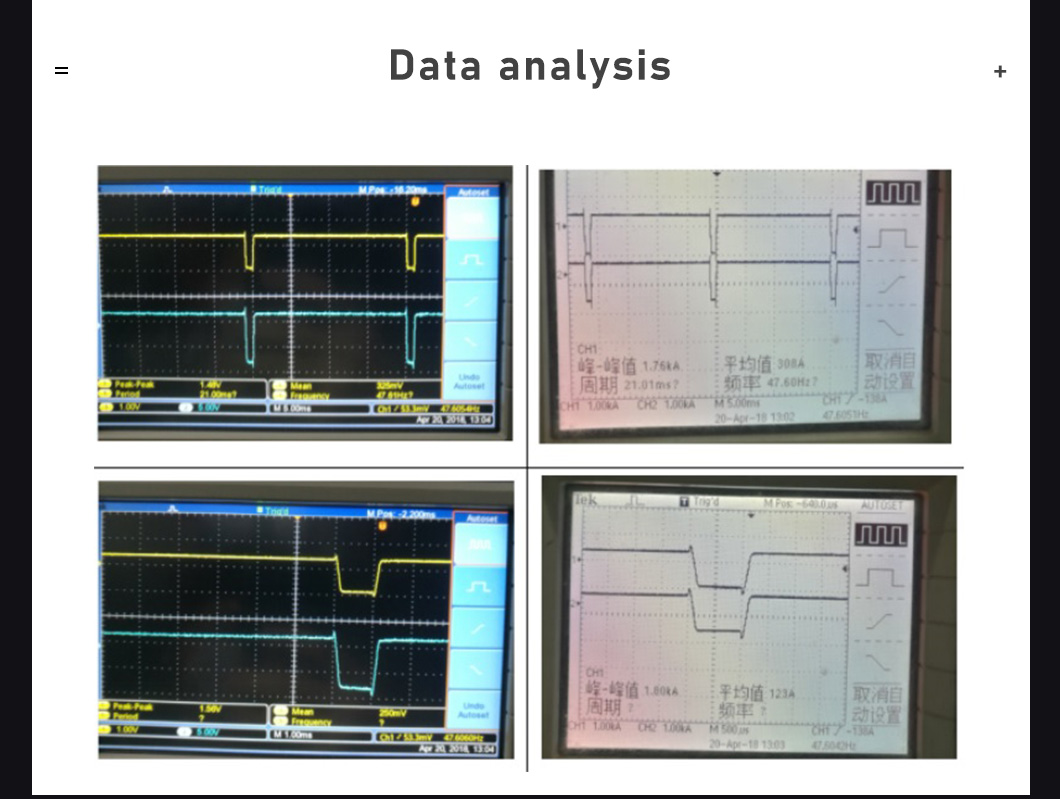

Output parameters: Positive: DC 10V 2*1000A Negative: DC 30V 2*3000A

Output mode: High speed positive and negative pulse

Cooling method: Water cooling

Power supply type: High-frequency power supply

Application Industry: PCB plating, rare metal plating, precision design, precious metal plating, electrolytic polishing, etc

PCB plating may be defined as one or both of the following: Via plating – the process of filling a drilled hole with copper to provide a path for current from a surface of the board to an inner layer, between two inner layers or from one surface to the other. These plated through holes (PTHs) are better known as vias.

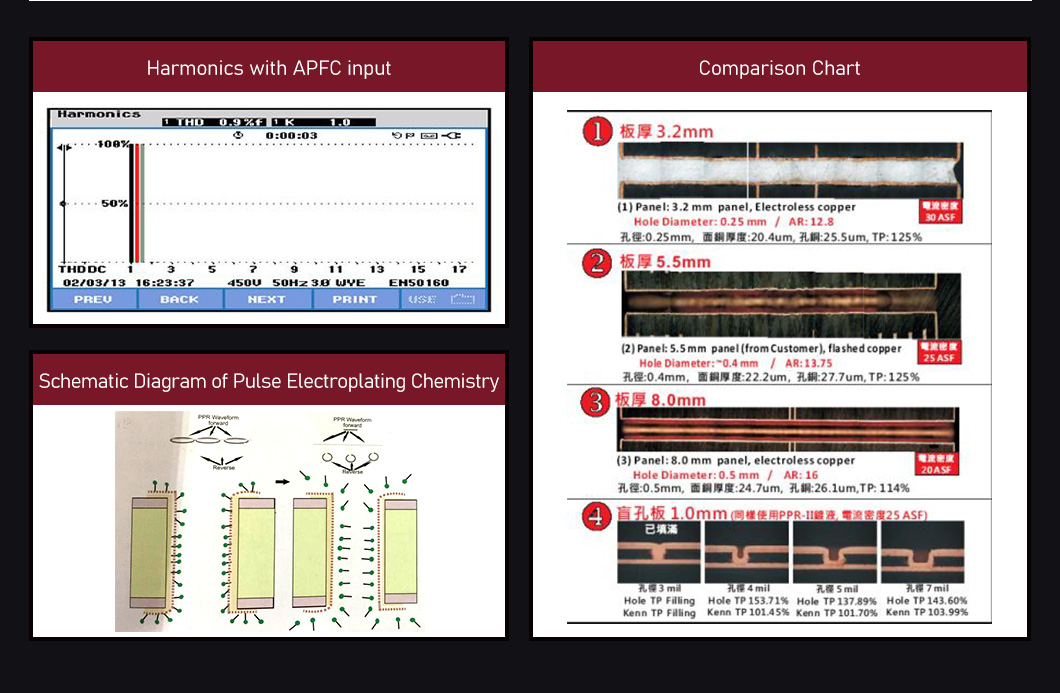

In the process of plating onto bare laminate, electroless copper plating plates a thin layer of copper on the bare substrate to make the substrate conductive for further electroplating. In the process of plating through hole, electroless copper plating is used to make the inner walls of the hole conductive to connect the printed circuits in different layers or the pins of the integrated chips.

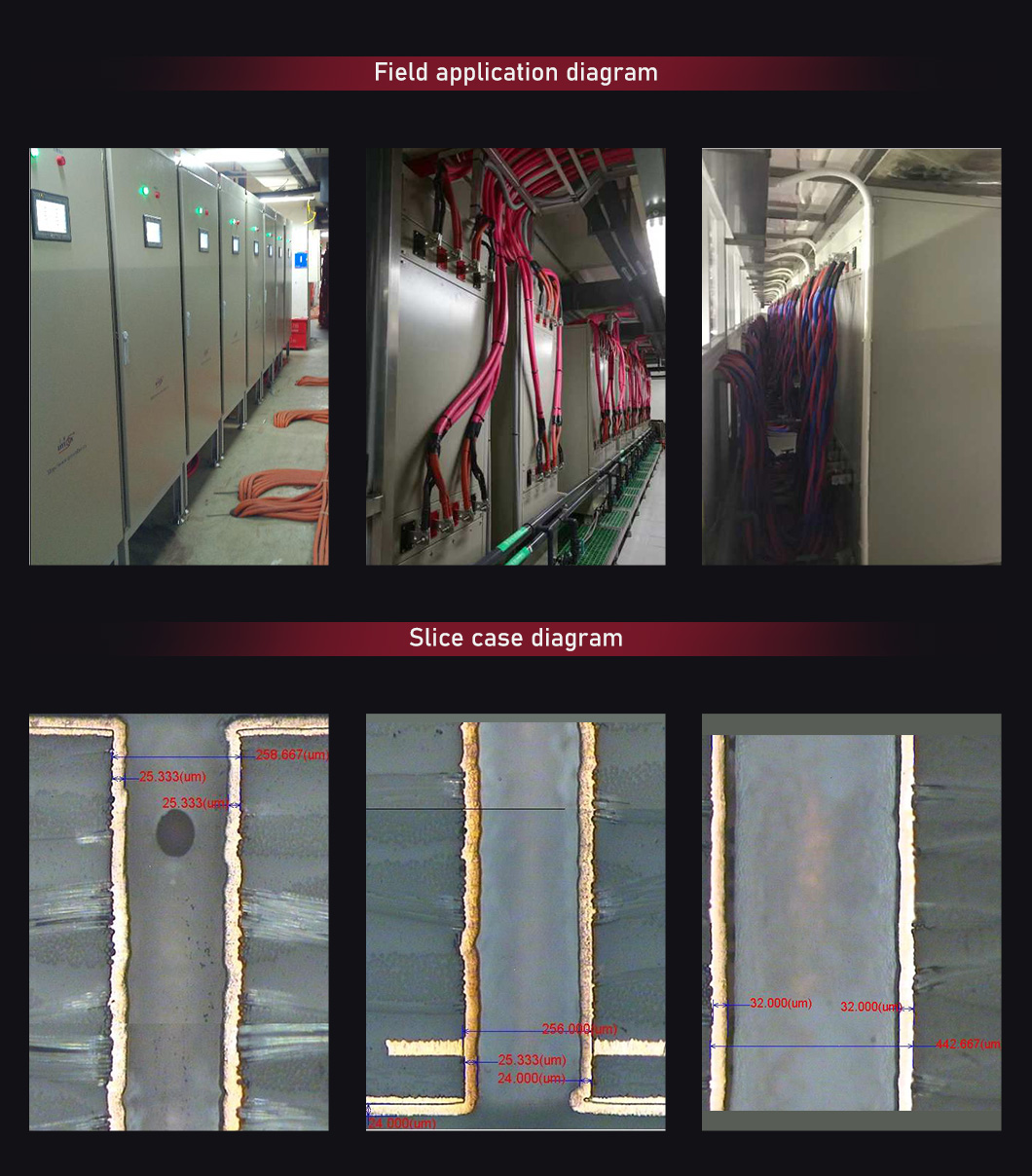

When through hole used dc plating, the thicker the plating around the hole is, and there is no plating in the hole. The two ends are big and the middle is small. This dog bone phenomenon is prone to copper cracking, or no electricity at all.

Positive and negative pulse power supply can increase electroplating speed. Improve the uniformity of copper plating, deep hole plating uniformity; Reverse pulse electroplating can control the deposition rate of copper in the high current density area, so as to improve the thickness uniformity of surface copper and pore copper, and eliminate the “dog bone” phenomenon.

Characteristic Types |

Parameter Items |

Technical Requirements |

| Power Types | Power types | High-frequency Power Supply |

| Model and specifications | HPNPS-2*Z1000AF3000A/6V | |

| Cooling mode | Water-cooled | |

| Switch tube type | IGBT | |

| Input Characteristics | Rated Input Voltage | Three-phase,AC380V±10% ,50HZ |

| Rated Input Power | 26KVA | |

| Rated Input Current | AC 39.5A | |

| Input Power Factor | COSΦ≥0.90 | |

| Output Characteristics | Output Voltage | DC +10V/-30V |

| Output Current | DC 2*+1000A/2*-3000A | |

| Stabilized Current Precision | ≤1%(Rated Current) | |

| Stabilized Voltage Precision | ≤1% | |

| According to accuracy | 1A,0.1V | |

| Rated Output efficiency | ≥90% | |

| Environmental Conditions | Installation site | Indoor installations |

| Altitude | ≤2000 meters | |

| Ambient temperature | -20℃~40℃ | |

| Relative humidity | ≤90% | |

| Control Mode | Operating mode | PLC, ADDA, Ethernet, RS485 and RS232 |

| Weight | Net weight | About 400KG |

| Dimension | Height*Width*Depth | H860mm×W700mm×D930mm |

| Protection Characteristics | With over voltage, over current, overload, short circuit, overheating and other abnormal self-protection function | |

Hot Tags: +10V -30V Water cooled pulse rectifier for plating,PCB plating, rare metal plating, electrolytic polishing, High-frequency Power Supply,Advantages of our pulse power supply,Pulse Power Supply,PCB Electroplating

If you have more questions, please leave us a message and we will contact you within 24 hours.